Tank calibration is a procedure that adjusts the accuracy of the fuel level display system in the tank. This procedure converts fuel level sensor (FLS) readings to liters or volume of fuel in the tank. To perform a fuel tank calibration, the fuel level is measured and compared to the actual amount of fuel filled. The method of calibration depends on the dimensions and shape of the tank.

Customers often ask why the procedure of fuel tank calibration in your company is so expensive and takes so long? After all, other companies offer a similar service almost twice cheaper and perform it in only 20 minutes.

Fuel tank calibration procedure

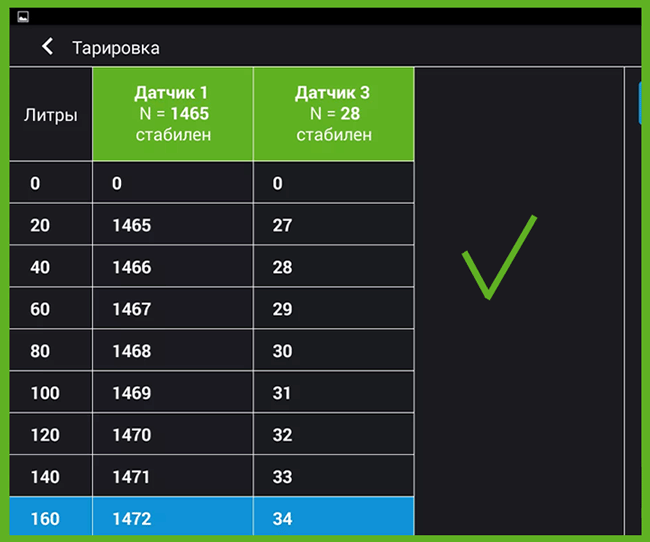

To ensure accurate and correct operation of the fuel level sensor (FLS) it is necessary to calibrate the fuel tank. According to the requirements of equipment manufacturers, when calibrating the tank, it is necessary to perform at least 20 dosed fuel fillings, which is specified in the fuel gauge passport. These actions are necessary to create a calibration table, which correlates the level of fuel in the tank with its volume.

Number of spills for tank calibrations

For example, for a 600-liter tank one dosed fill will be 600/20=30 liters, i.e. it is necessary to fill the fuel 20 times with 30 liters (and this is the minimum requirements, often there are much more spills). Each such spill takes about 3 minutes. The procedure of calibration is as follows: it is necessary to fill the fuel, wait until the fuel settles and the foam goes away. For calibration of a 600 liter tank it will take at least 60 minutes (3 minutes for 20 spills). In addition, after calibration it is necessary to carry out a control drain or refueling to check the correctness of the data, which will take from 20 to 50 minutes.

Do all companies do tank calibrations?

Some companies charge a fee for fuel tank calibration, but don't actually do it. Instead, they install an ROV and set the MIN/MAX values, but don't actually spill the fuel. This may show the fuel level in the tank, but the RTC readings will be inaccurate.

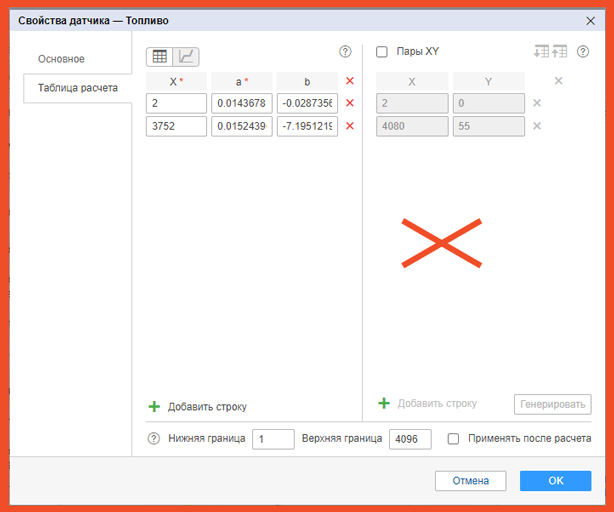

To verify the quality of the tank tare performed, you should request a tare table from your service provider. If the calibration table is not provided or contains only 2 values, the tank has not been properly calibrated. In this case, a fuel spill is performed with an insufficient number of fillings - less than 10 when 20 are required. Examples of incorrect calibration table are given below.

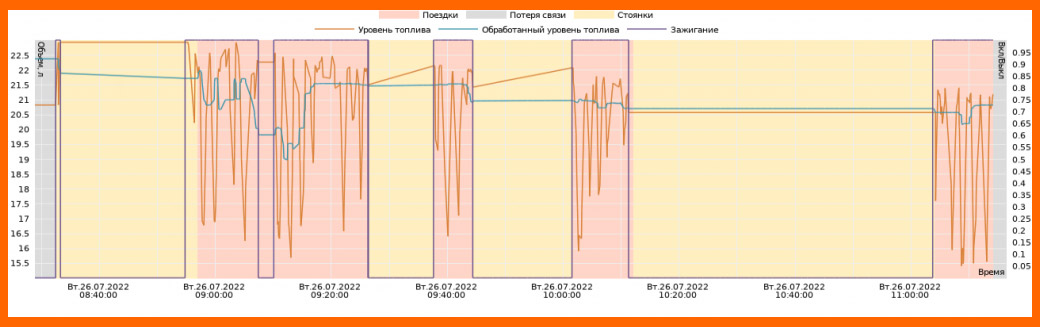

In addition, the monitoring program will have distorted data on fuel consumption, large fluctuations, as well as will not converge drains and fueling.

Professional tank calibration

MONTRANS installers use high-precision calibration stations, adhere to the regulations and recommendations of fuel level sensor manufacturers, and use certified measuring tanks.

Thanks to high-quality installation, calibration and calibration of sensors and tank, the customer can be confident in the reliability of data and rely on the GPS/GLONASS fuel control and transportation monitoring system.

Correctly performed calibration allows to accurately display the fuel level in the tank in the monitoring system, which helps to save fuel and increase the efficiency of vehicle utilization.

Correctly performed calibration allows to accurately display the fuel level in the tank in the monitoring system, which helps to save fuel and increase the efficiency of vehicle utilization.

Our specialists can work in any weather conditions, while complying with regulations and instructions, and are provided with all the necessary accessories and tools for the work.

As we can see, installation, calibration and taring of the sensor in the fuel tank is a complex process, which affects the cost of the service. And here we can say - “Price = quality”

Service application

To control the installation of vehicle monitoring systems and fuel consumption control, we use a modern service system, which allows you to track the installation and calibration process at any stage, stores the history of the vehicle, as well as can be used:

- Self-submit requests to the support service

- Control the status of fulfillment of your requests

- Communicate with the technical support service via comments, including voice.

- Attach files and photos of the “fault” directly from your phone

- Confirm or reject the request fulfillment

- Rate the support team

- Receive PUSH notifications on your requests

- Control the status of fulfillment of your requests

- Communicate with the technical support service via comments, including voice.

- Attach files and photos of the “fault” directly from your phone

- Confirm or reject the request fulfillment

- Rate the support team

- Receive PUSH notifications on your requests

When choosing a provider of transportation monitoring services, you should pay attention to how the company performs the sensor calibration procedure and whether it has standards for its performance. Insufficiently performed fuel tank calibration or its absence can lead to significant errors in determining the volume of fuel refueling and fuel draining, which in turn can lead to the inability to correctly control fuel consumption. This is especially important if you value your time and resources.