20+

Years of experience

11

Branch offices

25000+

Facilities under service

22

Regions of operation

Our social media

India:

Uzbekistan:

Fuel control on fuel tankers

From small tank, to large tanks.

up to 40% fuel savings

In-house production

An uncontrolled fuel tanker can be compared to an object of easy profit for drivers. The equipment, which should work for its owner and bring him money, loses tens of thousands of rubles every month.

This was the case before the MONTRANS fuel control complex appeared on fuel tankers

This was the case before the MONTRANS fuel control complex appeared on fuel tankers

Less than 1% error

As a result of modernization, the fuel tanker can become a mobile, digital, high-tech filling station.

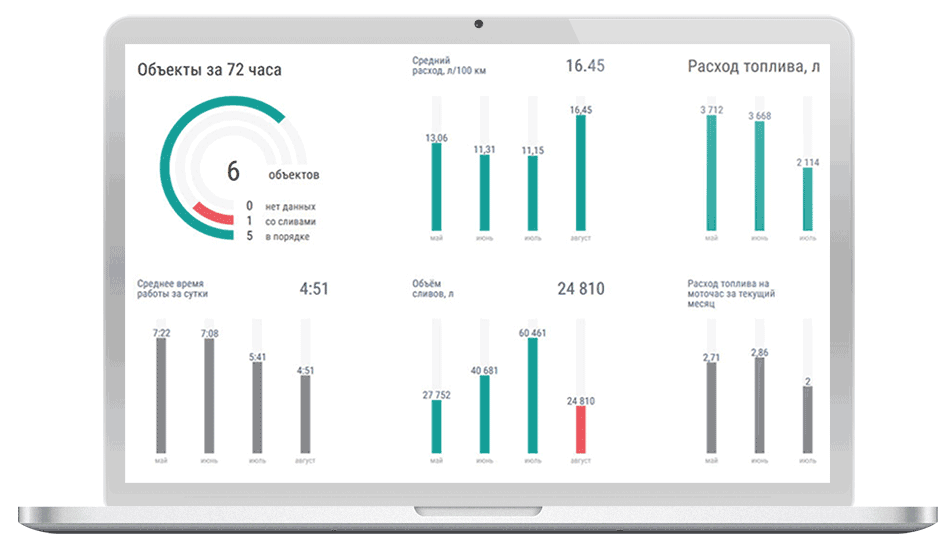

Modern fuel control at the fuel refueling station

Modern MONTRANS solutions allow to make fuel movement in the fleet absolutely transparent. Satellite monitoring eliminates the influence of human factor on fuel and lubricant receipts and distribution at the enterprise.

In fuel trucks, accounting consists of two components.

▸The first is the tractor's own consumption (controlled by digital fuel level sensors MONTRANS).

▸The second is the receipt and dispensing of fuel and lubricants to other vehicles. The MONTRANS fuel metering system (FMS) is designed for this purpose.

In fuel trucks, accounting consists of two components.

▸The first is the tractor's own consumption (controlled by digital fuel level sensors MONTRANS).

▸The second is the receipt and dispensing of fuel and lubricants to other vehicles. The MONTRANS fuel metering system (FMS) is designed for this purpose.

FMS is the newest automated control system for fuel distribution and control on gasoline tankers. The device is designed to collect, store and transmit information on the complete cycle of fuel and lubricants movement at enterprises: shipment from a warehouse or oil refinery, delivery and discharge of fuel into stationary storage facilities, refueling from stationary storage facilities into fuel tankers, refueling of vehicles from fuel tankers, control of fuel consumption by each individual unit of equipment.

The controller detects the fuel level in tanks, cisterns and stationary containers. Before refueling, the FMS identifies the driver and the vehicle. The controller shows how much fuel has passed through the refueling gun by reading the data from the mechanical counter. The device transmits the date, time and geographical coordinates of the refueling place to the operator.

If necessary, a daily fuel dispensing limit can be prescribed for each electronic card. As a result, the driver will not be able to receive more fuel than the norm. The controller transmits information to the server via GSM or WI-FI channels.

MONTRANS equipment is installed on all types of vehicles intended for transportation of dangerous goods. Including fuel tankers. In such cases, the company uses explosion-proof sensors, special devices for safe signal acquisition, and protected connection cables.

If necessary, a daily fuel dispensing limit can be prescribed for each electronic card. As a result, the driver will not be able to receive more fuel than the norm. The controller transmits information to the server via GSM or WI-FI channels.

MONTRANS equipment is installed on all types of vehicles intended for transportation of dangerous goods. Including fuel tankers. In such cases, the company uses explosion-proof sensors, special devices for safe signal acquisition, and protected connection cables.

MONTRANS equipment is installed on all types of vehicles designed for the transportation of dangerous goods. The company applies innovative solutions on fuel tankers, which control the movement of fuel with high precision and help to make all processes as safe as possible.

At the customer's request, a fuel volume display (LLD) can be installed in the vehicle cab. The display shows the current values of fuel quantity in all tanks of the fuel tanker. The indicator helps the driver to control the volume of fuel and lubricants in order to replenish the stock in time.

For example, the electrical circuits utilize an intrinsic protection unit (IPU) that links a fuel level sensor located in a hazardous area to an external device located in a safe area.

A special cable (KTZ) is used to connect the BIS with the fuel level sensor. The cable protects the wires with a metal sleeve and PVC insulation. The length of KTZ is from 10 to 20 meters.

A signal acquisition device (SAD) is also used in the circuit. It is installed between the counter and the pointer. The SAD converts the rotation of the meter shaft into electrical impulses that are sent to the MONTRANS on-board terminal. The number of pulses is proportional to the volume of fuel dispensed. With the help of the SAD it is possible to control the volume of fuel delivered to the tankers of the fuel tanker, as well as the amount of dispensed fuel and lubricants. The signal acquisition device does not violate the metrological verification of the meter and does not require calibration.

✔ Controls the complete cycle of fuel movement at the enterprise

✔ Eliminates human factor from the fuel transfer process

✔ Collects, stores and transmits data on refuelings and discharges

✔ Transmits the date, time and coordinates of the refueling location to the operator

✔ Can be operated in harsh climatic conditions

✔ Can be connected to the standard fuel dispensing meter

✔ Can set daily limits on the volume of fuel dispensed

✔ Allows electronic statements to be received, reducing paper workflow

✔ Makes control over fuel consumption as safe as possible

✔ Saves staff time

✔ Enables significant savings in the company's budget

✔ Eliminates human factor from the fuel transfer process

✔ Collects, stores and transmits data on refuelings and discharges

✔ Transmits the date, time and coordinates of the refueling location to the operator

✔ Can be operated in harsh climatic conditions

✔ Can be connected to the standard fuel dispensing meter

✔ Can set daily limits on the volume of fuel dispensed

✔ Allows electronic statements to be received, reducing paper workflow

✔ Makes control over fuel consumption as safe as possible

✔ Saves staff time

✔ Enables significant savings in the company's budget

Benefits of monitoring on fuel trucks:

Uncontrolled fuel consumption at remote sites is a headache for every fleet owner. Mobile tankers refuel vehicles in Siberian fields, underground in mines, in fields, in the mountains, in faraway lands and in places where Macar's calf does not graze. For example, 10 tons of fuel oil were poured into a barrel, but only the driver of the fuel tanker knows how much fuel got into the tanks of cars. There were cases when up to half of the fuel volume from a gas tanker went "to the left".

The transport monitoring system has radically changed the situation in favor of the management of enterprises. Telematics keeps records and controls fuel consumption via GLONASS/GPS channels. Fuel level sensors (FLS) in the tank of each vehicle transmit data on the volume of fuel and lubricants in real time. The dispatcher can see on the computer monitor all refueling of vehicles, oil products consumption and drains, if they occur. As for the fuel tanker, it is equipped with a fuel metering system (FMS). This refueling module is the last word in the distribution and control of fuel and lubricants in road transport companies. The FMS makes the movement of fuel in the company absolutely transparent and helps to save up to 30% of the budget. One of the most important factors for achieving such savings is the exclusion of human involvement from the fuel dispensing process. Thus, the MONTRANS fuel consumption control system works online in automatic mode. This greatly simplifies the operator's work and fleet maintenance.

MONTRANS controller is a multifunctional device. It collects data on the movement of light oil products, stores the information and transmits it to the cloud service. The control starts from the moment of fuel and lubricants shipment from the warehouse to the fuel carriers' tanks. Further, FMS tracks fuel discharge into stationary storage facilities, subsequent pumping into fuel tankers, delivery of fuel oil or gasoline to the place of equipment operation and fuel dispensing for each vehicle. Data on the amount of fuel and lubricants in the tank of the refueler is constantly transmitted to the company's server. The dispatcher monitors fuel supply, refueling, controls the limits and parameters of vehicles that can receive fuel. If the vehicle operates outside the GSM coverage area, the MONTRANS refueling module goes offline and continues to function. When communication is available, the data is updated.

The FMS can be used for any tank that stores fuel and lubricants - whether it is a stationary barrel or a mobile refueling truck. The controller is installed after installation of the pump, meter and fuel filter. On fuel dispensers, the device is connected to the regular fuel dispensing meter.

Before starting refueling, the MONTRANS controller identifies the driver and the vehicle. The company administrator sets the parameters of all persons who can receive fuel in the program. Data reconciliation and admission to refueling can take place in several ways:

- pin-code entry on the keyboard

- using a plastic card

- using contactless RFID tags

- in case of card loss - remote authorization from the server

The transport monitoring system has radically changed the situation in favor of the management of enterprises. Telematics keeps records and controls fuel consumption via GLONASS/GPS channels. Fuel level sensors (FLS) in the tank of each vehicle transmit data on the volume of fuel and lubricants in real time. The dispatcher can see on the computer monitor all refueling of vehicles, oil products consumption and drains, if they occur. As for the fuel tanker, it is equipped with a fuel metering system (FMS). This refueling module is the last word in the distribution and control of fuel and lubricants in road transport companies. The FMS makes the movement of fuel in the company absolutely transparent and helps to save up to 30% of the budget. One of the most important factors for achieving such savings is the exclusion of human involvement from the fuel dispensing process. Thus, the MONTRANS fuel consumption control system works online in automatic mode. This greatly simplifies the operator's work and fleet maintenance.

MONTRANS controller is a multifunctional device. It collects data on the movement of light oil products, stores the information and transmits it to the cloud service. The control starts from the moment of fuel and lubricants shipment from the warehouse to the fuel carriers' tanks. Further, FMS tracks fuel discharge into stationary storage facilities, subsequent pumping into fuel tankers, delivery of fuel oil or gasoline to the place of equipment operation and fuel dispensing for each vehicle. Data on the amount of fuel and lubricants in the tank of the refueler is constantly transmitted to the company's server. The dispatcher monitors fuel supply, refueling, controls the limits and parameters of vehicles that can receive fuel. If the vehicle operates outside the GSM coverage area, the MONTRANS refueling module goes offline and continues to function. When communication is available, the data is updated.

The FMS can be used for any tank that stores fuel and lubricants - whether it is a stationary barrel or a mobile refueling truck. The controller is installed after installation of the pump, meter and fuel filter. On fuel dispensers, the device is connected to the regular fuel dispensing meter.

Before starting refueling, the MONTRANS controller identifies the driver and the vehicle. The company administrator sets the parameters of all persons who can receive fuel in the program. Data reconciliation and admission to refueling can take place in several ways:

- pin-code entry on the keyboard

- using a plastic card

- using contactless RFID tags

- in case of card loss - remote authorization from the server

Igor Elsukov, Head of Analytical Department of MONTRANS Group of Companies: "At the request of the ATP management, a shift, daily, weekly or monthly limit of fuel and lubricants can be set for each unit of equipment. In this case, the driver will not be able to fill up more fuel than it is set in the program. At the same time, the limits are updated online for all fueling trucks of the company. The controller can be installed on both new and existing vehicles. The automatic fuel dispenser can operate from 12, 24, 220 or 380 volts.

MONTRANS FMS has the following advantages:

- Total control of fuel and lubricant movement in the fleet

- Collection and storage of all fuel movement data

- No human influence on fuel distribution

- Fixes the coordinates of the refueling place, date and time

- Operated in any climatic conditions

- Sets fuel dispensing limits

- Use of electronic statements

- Saves working time of employees

- Saves company budget

- Total control of fuel and lubricant movement in the fleet

- Collection and storage of all fuel movement data

- No human influence on fuel distribution

- Fixes the coordinates of the refueling place, date and time

- Operated in any climatic conditions

- Sets fuel dispensing limits

- Use of electronic statements

- Saves working time of employees

- Saves company budget

Alexander Seleznev, fuel and lubricants and road safety engineer at KVS International: "After the cameras were installed, we found out that every time we refueled, 50-100 liters of fuel was underfilled. We presented video recordings to the culprits. The amounts of stolen fuel were deducted from their salaries.

The automated fuel dispensing system is customizable and the MONTRANS FMS can be adapted to the needs of companies operating in different industries. The terminal has a high degree of protection against vibration, shock, moisture and dust. In addition, the refueling module can be integrated with any accounting systems. For example, KWS International has installed controllers on the fuel tanks of GENTAX water heating equipment. The volume of the tanks is 500 and 1500 liters. Management suspected that drivers were draining fuel oil in large quantities for their own use. In addition, a MONTRANS DVR video surveillance system was installed for double control. The cameras were placed on the tank necks and also on the return connection.

Installation and application of the automated fuel accounting controller is regulated by the Government Decrees No. 2216 "On Approval of the Rules for equipping vehicles of M2, M3 and N categories used for transportation of dangerous goods with satellite navigation equipment", as well as PP No. 969 "On Approval of the Requirements to the Functional Properties of Technical Means of Transport Security and the Rules of Mandatory Certification of Technical Means of Transport Security".

The practice of MONTRANS FMS application over the last year has shown that fuel and lubricant savings in vehicle fleets reach 30%. The controller pays for itself within 3 to 6 months.

Installation and application of the automated fuel accounting controller is regulated by the Government Decrees No. 2216 "On Approval of the Rules for equipping vehicles of M2, M3 and N categories used for transportation of dangerous goods with satellite navigation equipment", as well as PP No. 969 "On Approval of the Requirements to the Functional Properties of Technical Means of Transport Security and the Rules of Mandatory Certification of Technical Means of Transport Security".

The practice of MONTRANS FMS application over the last year has shown that fuel and lubricant savings in vehicle fleets reach 30%. The controller pays for itself within 3 to 6 months.

Check if MONTRANS digital fleet management is the right fit

Please provide your contact details to complete the request. Our manager will get in touch with you soon.